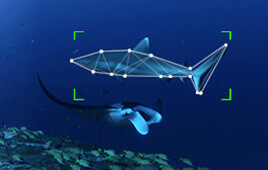

Summary of the solution

The client required a vision-based quality control inspection system to auto-capture/detect product defects in real-time on the edge. See how e-con Systems enabled the client to achieve lower risks, higher cost savings, and smoother operations despite having to inspect products in harsh environments!

Key challenges faced by the client

Unpredictably large-sized material

surfaces on which defects

had to be detected

Uncompromisingly high

level of quality

(detecting minor defects)

Mr. Thomas Yoon

Mr. Thomas Yoon +82-10-5380-0313

+82-10-5380-0313