Image sensors such as CMOS have seen their use cases grow significantly in size across many industries today. And you can also see major differences among the designs of the image sensors. For instance, these sensors come in varying sizes.

Undoubtedly, the size of the camera sensor is a major parameter that influences key aspects of imaging, including factors such as sensitivity, resolution, dynamic range, and low-light performance. Understanding sensor size and its implications for camera performance is critical in the development and optimization of imaging solutions.

In this blog, you’ll gain expert insights by comparing different sensor sizes and knowing their use in embedded vision applications.

But first, let us first try to understand what a CMOS sensor is and how its size is measured.

What is a CMOS sensor?

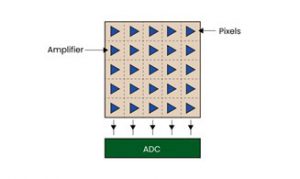

CMOS (Complementary Metal-Oxide Semiconductor) is a digital device for capturing light and converting it into electrical signals. It has a photodiode and a transistor switch for each pixel. When light strikes the pixel, it creates a voltage proportional to intensity. The voltage is sampled directly at the pixel.

Having an amplifier for each pixel allows the pixel signals to be amplified individually, as shown in the below figure.

Figure 1: CMOS Sensor Architecture

Figure 1: CMOS Sensor Architecture

Read: CMOS sensors vs CCD sensors: why CMOS sensors are ruling the world of embedded vision?

Benefits of Using CMOS Sensors

- Higher frame rate: CMOS sensors can capture multiple frames per second for real-time imaging and analysis.

- High resolution: CMOS sensors ensure high resolution so that applications can deliver exceptional imaging capabilities.

- Larger FoV: CMOS sensors provide a larger FoV for wide-angle imaging while equipping applications to capture large objects/scenes.

- Cost-effectiveness: CMOS sensors offer reduced costs, especially in comparison to CCD sensors.

- Power consumption: CMOS sensors draw less power, which is useful in embedded vision systems that have other power-hungry components.

- Current trend: The increasing adoption of CMOS sensors is causing manufacturers to shift focus away from development of other sensors.

Read: CMOS sensors vs CCD sensors: Why CMOS sensors are on top

Read: Five crucial features that highlight the advantage of CMOS cameras

What does camera sensor size mean? How is it measured?

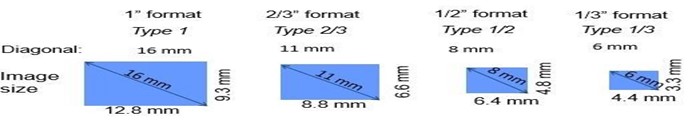

CMOS sensors are generally specified by their physical sizes. The size of the CMOS sensor determines the light-collecting surface area of the sensor. The dimensions of the sensor are defined by the resolution and the pixel size. As you may know, the size of a sensor is often measured in inches. The image sensor format is sometimes referred to as sensor size or optical format.

The value of optical format is the approximate multiplication of the diagonal length of the sensor and 3/2.

Optical format = (3/2) * Diagonal of Sensor

For example, consider the AR1335-CMOS image sensor from onsemi™ that has a sensor size of 4.54×3.42 mm and a diagonal of 5.68 mm. Therefore, the optical format is 5.68*3/2 = 8.52 mm, which is expressed as 1/3.2″.

Likewise, there are several sensor sizes available in the market as shown in the following figure.

Figure 2: Illustration of Sensor Size Dimensions

Figure 2: Illustration of Sensor Size Dimensions

CMOS sensor size comparison

The below table shows the comparison of different sensor sizes and the corresponding crop factors:

| Type | Diagonal (mm) | Width (mm) | Height (mm) | Area (mm²) | Crop factor |

| 1/2″ | 8 | 6.4 | 4.8 | 30.7 | 5.41 |

| 1/2.3″ | 7.66 | 6.17 | 4.55 | 28.5 | 5.64 |

| 1/2.5″ | 7.18 | 5.76 | 4.29 | 24.7 | 6.02 |

| 1/3″ | 6 | 4.8 | 3.6 | 17.3 | 7.21 |

| 1/3.2″ | 5.68 | 4.54 | 3.42 | 15.5 | 7.61 |

| 1/4″ | 4.5 | 3.6 | 2.7 | 7.92 | 10.81 |

| 2/3″ | 11 | 8.8 | 6.6 | 58.1 | 3.93 |

| 35mm full-frame | 43.1–43.3 | 35.8–36 | 23.9–24 | 856–864 | 1 |

It is important to note that the crop factor is related to the ratio of the camera sensor’s size to a 35 mm film frame.

Crop Factor = Diagonal35mm / Diagonalsensor

How to choose the right CMOS sensor size for an embedded vision application

Each application has different sensor size requirements to produce images. Let us discuss the factors to be considered while choosing a sensor of a particular size.

- Resolution

- High frame rate and global shutter

- Sensitivity

- Lens mount selection

- Image circle diameter

- Low light performance

Resolution

Resolution is the ability of imaging systems to reproduce the exact object detail. Many embedded vision applications like autonomous mobile robots (AMR) and autonomous vehicles demand cameras to achieve precise 3D depth measurement. This would be achieved with the high-resolution feature of that camera. Selecting sensors with large pixel sizes is likely to have higher resolution.

Also, the resolution of the lens must match the pixel size of the sensor to achieve high-quality images. The quite popular camera resolution of 1600 x 1200 pixels often uses a larger sensor with a size of 1/1.8″, and now high-end 4K resolution uses a 1/1.2″ image sensor format.

High Frame Rate and Global Shutter

Embedded vision applications like automated license plate recognition, gesture recognition, robotic vision, drones, and AMR require high frame rate and global shutter features – depending on the nature of the end application. AR0234 from Onsemi is one of the most popular sensors used in such applications.

It is a 1/2.6″ (Diagonal 6.8 mm) optical format CMOS sensor with a 3.0 μm x 3.0 μm pixel size. It is a global shutter sensor that is used for accurate and fast capture of moving scenes at 120 frames per second at full resolution. See3CAM24_CUG from e-con Systems is a color global shutter camera based on the ARO234 sensor.

Explore: e-con Systems’ See3CAM24_CUG – a color global shutter camera based on the ARO234 sensor

Also, some of the other available sensor sizes are 1/2.9″ (for Omnivision’s OV2311 CMOS image sensor with 3.0 μm x 3.0 μm pixel size) and 1/3″ (Onsemi’s AR0134 CMOS digital image sensor with an active pixel array of 1280H x. 960V).

Sensitivity

Large sensors tend to have large pixel sizes, and this indicates higher sensitivity. To achieve high sensitivity and compact design, an industrial camera usually uses a 1/2.8″ CMOS image sensor.

This enables a high level of image recognition and detection performance for improved safety for smart city, surveillance, and traffic monitoring systems.

Lens Mount Selection

Mount is used for attaching a lens to a camera body. The selection of mount depends on the sensor size. For instance, the C mount, which is the type of lens mount for machine vision cameras, is appropriate for a 1.5″ sensor. S mount lens, which is commonly used in industrial applications, is appropriate for a sensor size of 1/2″, 1/3″ or smaller.

Image Circle Diameter

Industrial cameras might have issues like lens vignetting/lens shading, which is a gradual reduction of an image’s brightness or saturation from the image center to the four corners/ edges. This happens when the image format (or circle) of the lens is too small for the size of the sensor. So, to mitigate this, the image circle diameter must fit or be larger than the sensor size.

Low-light Performance

As discussed before, a large sensor contains larger photosites that are more receptive to light, thereby enhancing the camera’s ability to capture low-light images in comparison to a small sensor. Two of the popular sensor sizes targeted for low light performance are 1/1.2″ ( such as the Sony® IMX485 based 4K-resolution CMOS image sensor) and 35mm full-frame.

As advancements continue in sensor technology, there remains a constant pursuit of enhanced performance from sensors of varying sizes. However, it’s undeniable that in many scenarios, larger sensors offer superior performance.

Yet, it’s important to acknowledge that with increased size comes higher costs, making larger sensors typically more expensive compared to their smaller counterparts.

e-con Systems – A Leader in Providing CMOS Sensor-Based Cameras

e-con Systems, with 20+ years of experience in designing, developing, and manufacturing OEM cameras, has a track record of equipping clients with world-class CMOS camera modules. Some of the use cases we have successfully covered include industrial, retail, agricultural, medical, and more. These modules are seamlessly compatible with several embedded platforms, including NVIDIA Jetson. Our portfolio includes sensors from various manufacturers, covering a broad spectrum of sizes and capabilities. Below is a comprehensive table of the sensor sizes and corresponding sensor names in our portfolio.

|

Sensor Size |

Sensor Names |

||||||

|

1/1.2 |

|

|

|

|

|

||

|

1/1.7 |

|

|

|

|

|

|

|

|

1/1.8 |

|

|

|

|

|

||

|

1/2.3 |

|

|

|

|

|||

|

1/2.42 |

|

|

|

|

|

|

|

|

1/2.5 |

|

|

|

||||

|

1/2.6 |

|

|

|

|

|

|

|

|

1/2.7 |

|

|

|

|

|

|

|

|

1/2.8 |

|||||||

|

1/2.9 |

|

|

|

|

|||

|

1/3 |

|

|

|

|

|||

|

1/3.2 |

|

|

|

|

|

|

|

|

1/3.6 |

|

|

|

|

|

|

|

|

1/4 |

|

|

|

|

|

|

|

|

2/3 |

|

|

|

|

|

|

|

e-con Systems is also deeply committed to offer custom CMOS camera solutions that align with individual client needs. Our seasoned team of experts collaborates closely with clients to develop bespoke camera solutions. Our customization services include custom sensor selection, lens configurations, and integration with hardware and software components.

Visit the Camera Selector page to see our complete camera portfolio.

If you need help integrating CMOs camera modules into your products, please write to us at camerasolutions@e-consystems.com.

Prabu is the Chief Technology Officer and Head of Camera Products at e-con Systems, and comes with a rich experience of more than 15 years in the embedded vision space. He brings to the table a deep knowledge in USB cameras, embedded vision cameras, vision algorithms and FPGAs. He has built 50+ camera solutions spanning various domains such as medical, industrial, agriculture, retail, biometrics, and more. He also comes with expertise in device driver development and BSP development. Currently, Prabu’s focus is to build smart camera solutions that power new age AI based applications.