In our previous article, we discussed lens mounts commonly used in embedded cameras – and all the key factors to consider while picking the best lens mount for your application.

In this article, we will be showcasing an explicit comparison between C-mount and CS-mount.

To reinforce, these mounts are mechanical devices that firmly fasten a lens to a camera body. It is of utmost importance to pay attention to even the smallest details while picking a suitable mount type for different products.

First, let’s unearth some insights on C-mount and CS-mount.

A deeper look at C-mount and CS-mount

Both C-mount and CS-mount are screw-threaded type lens mounts, which defines their mounting style. These mounts are found in most machine vision cameras and surveillance cameras.

Each mount generally differs from the other by its size, inner/outer diameters, and flange focal distance (FFD). Now, while C-mount and CS-mount almost have the same specifications, the FFD differs.

Before looking into the similarities and differences between C-mount and CS-mount, let us understand the threading specifications.

Threading specifications

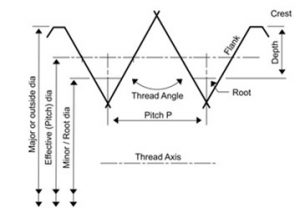

Each thread in the lens mount is characterized by its pitch and diameter. The following figure shows it consists of a crest, flank, and root as the repeating features along the thread axis.

Figure 1: Threading Specifications

Figure 1: Threading Specifications

Pitch

The pitch is the distance between the thread peaks and is expressed in millimeters. The pitch diameter refers to the diameter of the screw thread, as indicated in figure 1. A pitch of 1 means that each thread is spaced apart by 1 mm.

Major Diameter

Major diameter is the largest diameter of the thread – measured from the crest of the thread.

Minor Diameter

Minor diameter is the smallest diameter of the thread – measured from the root of the thread.

Thread Form

A thread form is defined by the standard called Unified Thread Standard (UTS). This standard designates standard thread shape along with allowances, tolerances, and designations. The UTS is commonly used in countries like the United States and Canada for screw threads.

Thread Class

A thread class refers to the acceptable range of pitch diameter for the thread. In general, a class defines how loose or tight the threads should be while mating. Thread classes are alphanumeric identifiers that start with a class number 1, as listed in the following table. These classes are followed by the letter suffix “A” or “B” for different design requirements. ‘A’ refers to external threading, and ‘B’ refers to internal threading.

| Unified Thread Class – Tolerance Range | |||

| Loose Fit | Free Fit | Medium Fit | |

| Internal | 1B | 2B | 3B |

| External | 1A | 2A | 3A |

Threads Per Inch

Threads Per Inch (TPI) is the number of threads across one inch of the thread length.

Technical Specifications of C-Mounts and CS-Mounts

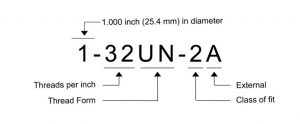

C-mounts and CS-mounts are available with the specification of 1-32 TPI UN-2A” in the ANSI B1.1 standard for unified screw threads. Check out the below image for a clear understanding of this specification.

Figure 2: Specification – C-mount and CS-mount

Figure 2: Specification – C-mount and CS-mount

The thread has a diameter of 1″ (25.4 mm) and 32 threads per inch. Both the C-mount and CS-mount have a metric thread of 25.5 mm diameter and pitch of 0.75 mm (M25.5×0.75).

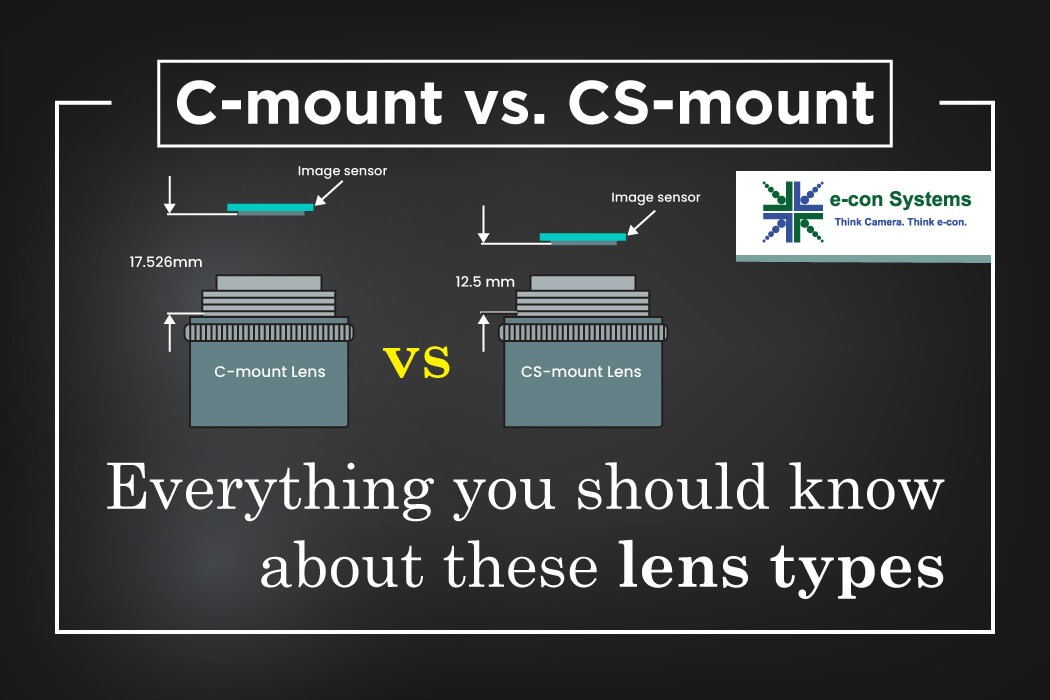

Flange Focal Distance

Flange Focal Distance (FFD) is the distance from the lens mount flange to the film/sensor. It is also known as flange-to-film distance, flange focal depth, flange focal length (FFL) or flange back distance (FBD). The standard FFD of the C-mount is 17.526 mm. On the other hand, the CS-mount features a flange distance of 12.5 mm, which is 5mm shorter than the FFD of the C-mount, as shown in the following figure.

Continue reading the article by providing your company email ID

We respect your privacy. Your email will only be used for content access validation.

Prabu is the Chief Technology Officer and Head of Camera Products at e-con Systems, and comes with a rich experience of more than 15 years in the embedded vision space. He brings to the table a deep knowledge in USB cameras, embedded vision cameras, vision algorithms and FPGAs. He has built 50+ camera solutions spanning various domains such as medical, industrial, agriculture, retail, biometrics, and more. He also comes with expertise in device driver development and BSP development. Currently, Prabu’s focus is to build smart camera solutions that power new age AI based applications.

Figure 3: FFD of C-mount and CS-Mount Lenses (Source: meijitechno)

Figure 3: FFD of C-mount and CS-Mount Lenses (Source: meijitechno)