With the complex use cases today’s embedded cameras have to serve, the number of factors product developers need to consider while selecting and integrating camera modules has also increased. In addition to selecting the right sensor, processor, and interface for the application, choosing the best-fit camera lens and lens mount is also significantly important. Matching the camera mount to the lens is critical in ensuring optimal image quality.

In this article, we’ll learn what lens mounts are, their types, and the factors you ought to consider while selecting one for your embedded vision system.

What are embedded camera lens mounts?

Lens mounts are mechanical devices that are used to securely attach a lens to a camera body. There are different versions of camera lens mounts for standard-size lenses as well as variable-sized versions that fit with a range of lens diameters. Also, lens mounts are available in different styles. However, the most commonly used mounting styles in embedded camera applications are screw-threaded type and bayonet-type.

Figure 1: Bayonet-type mount (Source: MIR)

As the name implies, screw-threaded type describes the action of threading your lens onto the camera body. On the other hand, bayonet-type uses three to four tabs to lock a lens tightly in place.

What are the different camera lens mount types?

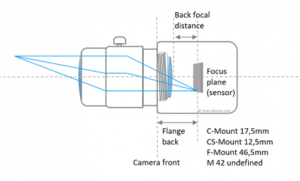

Many camera mounts have been in use for decades. But the most popular embedded camera mounts today are S-mount, C-mount, CS-mount, F-mount and T-mount. Each mount differs from each other by its throat size, inner and outer diameters, and flange distance (distance from the lens mount flange to the film/sensor). Cameras and lens manufacturers pick a suitable mount type for their products based on these parameters.

Let us now look at these popular mount types in detail.

S-mount

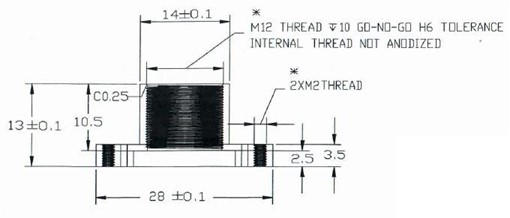

S-mount is a small lens mount system that comes with the screw-threaded mounting type. It is also known as M12-mount and is typically used in smart surveillance cameras and board-level cameras. This mount type has a metric thread of 12mm diameter and pitch of 0.5 mm (M12x0.5), where M stands for metric dimension in millimeters of the outside diameter. To understand in detail about the mechanical details, have a look at the below M12 lens holder mechanical diagram:

Figure 2: M12 Lens Holder Mechanical Diagram

Figure 2: M12 Lens Holder Mechanical Diagram

C-mount

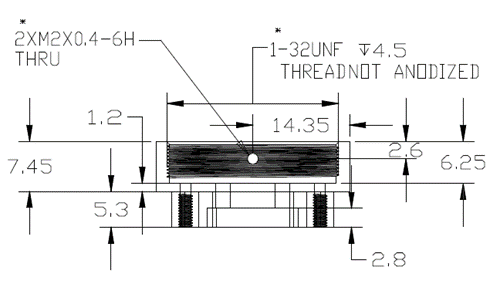

C-mount is the most common type of lens mount with the specification 1″ x 32 TPI UN 2A (threads per inch) and its standard flange focal distance (FFD) is 17.526 mm. This mount type has a metric thread of 25.5 mm diameter and pitch of 0.75 mm (M25.5×0.75). C-mount lens is directly compatible with C-mount camera. It can also be screwed onto a CS-mount camera using an adaptor – which is discussed in the upcoming section.

CS-mount

CS-mount has almost the same specification as that of C-mount but with a 5mm shorter flange focal length. It features a flange focal distance of 12.5 mm. The CS-mount standard is a prevailing standard for cost-sensitive embedded vision applications.

As the flange focal distance of CS-mount is 5 mm shorter than the focal distance of C-mount, using CS-mount on C-mount cameras is not possible. Whereas C-mount can be used on a CS-mount camera by inserting a CS-mount adapter (5 mm spacer ring) between the lens and the camera. Generally, the thickness of the lens adapter is purely dependent on the difference in focal flange distance.

Figure 3: CS-Mount Mechanical Diagram

F-mount

The F-mount is a bayonet type mount system basically developed for Nikon SLR and DSLR cameras. This mount type features a diameter of 44mm and a flange distance of 46.5mm. The bayonet type F-mount offers ease of use for manufacturers who work with line scan cameras and large format cameras.

T-mount

T-mount is quite different from the other mounts and is referred to as M42-Mount. This mount type is mainly required for high-tech cameras with particularly large and high-resolution sensors. This mount type features a metric thread of 42 mm diameter and pitch of 0.75 mm (M42x0.75). Its standard flange focal distance is 55 mm.

Camera Mount Comparison

| Lens Mount Type | Flange Focal Distance | Camera Formats | Throat Diameter | Mount Type |

| S | No standardized Flange distance | 1/6″ to 1″ | 12 mm | Screw |

| C | 17.526 mm | 8mm, 16mm, 1/3″, 1/2″, 2/3″, 1″, 4/3″ | 25.40 mm (1 inch) | Screw |

| CS | 12.50 mm | 1/4″, 1/3″, 1/2″ | 25.40 mm (1 inch) | Screw |

| Nikon F | 46.50 mm | 24X36 mm / APS-C | 44 mm | Bayonet |

| T | 55.00 mm | 24X36 mm | 42 mm | Screw |

Factors to consider while picking a lens mount for your application

Now that you understand what camera lens mount types are, let us learn the factors you need to consider while picking the lens mount for your application. They are as follows:

• Mount Size and Flange Distance

• Sensor Size and its Resolution

• Field of view (FOV)

• Focal length of the lens

• Focus

• Compact Size

Mount Size and Flange Distance

The size of the mount is an important factor in an embedded camera system. Generally, a larger mount size permits the use of larger lenses that allow more light to fall on the sensor. At the same time, mount size is not the only parameter that impacts lens design – flange distance is equally important. The mount with a shorter flange distance permits the lenses to be placed closer to the sensor. This in turn helps lens manufacturers to build simpler and less expensive short-focus lenses.

A shorter flange distance also allows to design compact cameras when compared to cameras with longer flange distances. In a nut shell, the perfect balance of mount size and flange distance in camera design is critical in delivering the best optical image quality in embedded camera applications.

The flange focal distances of some commonly used mounts are shown below:

Figure 4: Flange focal distance of Mounts (Source: Vision-Doctor)

Sensor Size and its Resolution

Many new-age embedded vision applications use large and high resolution sensors to meet the desired image quality standards. You need to make sure that the lens mount you pick can meet the maximum desired resolution. As the diameter of C-mount is small – 1 inch (25.4 mm) – it is not suitable for larger sensors such as those used in high-resolution cameras. F-mount is an ideal choice when the imaging sensor exceeds the 22 mm C-mount size limit. Also, T-mount is considered more robust for high resolution sensors or line scan cameras as it has a much larger diameter than a C-mount.

FOV

Recent technological advancements have impelled the introduction of wider FOV enabled lens mount. Despite the fact that C-mounts are most widely used in such applications, they are limited to a maximum FOV of up to 22 mm. Therefore, if FOVs greater than 22mm are required, C-mount will no longer be the mount of choice.

Looking further, F-mount is ideally suited for an FOV>22 mm. Also, F-mount adaptors allow an FOV greater than 30 mm.

Focal length of the lens

The focal length of the lens also determines the type of mount it can fit with. For instance, a lens with a long focal length like 50mm would require larger holder height, and such a lens cannot be connected to an M12 holder (as it is 12mm in diameter). M12-mount/CS-mount is usually suitable for shorter lengths.

Focus

The focus needs to be maintained to obtain the best image quality. In general, the back focal length and mount size of S-mount lenses are frequently incompatible with CS and C-Mount cameras, resulting in an out-of-focus image. Thus, the lens-to-mount combination must be appropriate for the best focus quality.

Compact Size

Compact embedded cameras can be built by mounting the sensor very close to the camera housing. The use of smaller mount size is popular in embedded vision systems that need to maintain a small form factor.

Typically, product developers prefer to go with an S-mount lens type than C/CS mount lenses in such applications due to its smaller size and common availability.

Cameras with different lens mounts offered by e-con Systems

e-con Systems offers a wide range of high-quality and high-performance S-Mount (M12), C-Mount and CS-Mount cameras for new age embedded vision applications. These lens holders support different types of lenses for various FOV, focal length, aperture, etc.

If you are interested in integrating S-mount (M12) and C/CS-mount cameras into your products, please write to us at camerasolutions@e-consystems.com. Meanwhile, please feel free to check out the Camera Selector to have a look at our complete portfolio of products.

Prabu is the Chief Technology Officer and Head of Camera Products at e-con Systems, and comes with a rich experience of more than 15 years in the embedded vision space. He brings to the table a deep knowledge in USB cameras, embedded vision cameras, vision algorithms and FPGAs. He has built 50+ camera solutions spanning various domains such as medical, industrial, agriculture, retail, biometrics, and more. He also comes with expertise in device driver development and BSP development. Currently, Prabu’s focus is to build smart camera solutions that power new age AI based applications.