Forklifts are a critical part of modern warehouse operations, enabling the lifting and transport of heavy loads with ease. However, they pose significant safety risks. Forklift-related accidents can lead to severe injuries or fatalities, making safety a critical concern for any organization.

Embedded cameras in these heavy vehicles play an integral role in navigating autonomously, performing functions such as mapping, path planning, localizing and obstacle avoidance.

In this blog, we will explore the importance of forklift safety, common hazards, and how the RouteCAM_CU25 can play a crucial role in enhancing forklift safety.

We will also introduce ForkVista, e-con Systems’ AI-powered next-generation camera solution for enhancing warehouse safety.

Why You Should Use Forklift Safety Cameras

Operating a forklift is far more complex than driving a regular vehicle. These indispensable tools in industrial environments facilitate the efficient lifting and transport of heavy loads. Despite their utility, forklifts pose various hazards that must be addressed to ensure operational safety and efficiency.

Common forklift safety hazards

Blind spots and limited visibility

Blind spots cause major issues for forklift operators, making it difficult to detect obstructions and pedestrians. This often leads to accidents and damage to both forklifts and inventory. Limited visibility also affects the accurate placement of loads, resulting in instability and potential accidents caused by improperly balanced or positioned goods.

Productivity loss and trial-and-error in load placement

Errors in forklift operations, often due to poor visibility and the need for excessive trial and error in load placement, can slow down tasks and reduce efficiency. Operators might need multiple adjustments to position the forklift’s forks correctly, wasting time and lowering overall productivity within the warehouse.

Limited integration with safety systems

Limited integration of various safety systems can leave certain blind spots unchecked, increasing the risk of accidents due to incomplete situational awareness. Effective safety management requires comprehensive systems that work together seamlessly to cover all potential hazards. Forklift safety cameras are the proven method to mitigate these risks.

Now, let us see how e-con Systems’ RouteCAM_CU25 provides valuable insights to ensure safer warehouse operations.

How e-con Systems’ RouteCAM_CU25 Enhances Forklift Safety

RouteCAM_CU25_IP67 is a Global Shutter GigE Camera that captures fast-moving scenes at 60 fps, delivering exceptional accuracy and detail. It hosts a variety of features ideal for applications in harsh environments requiring highly detailed image outputs.

This camera streams high-quality, compressed Full HD data in a range of industry-standard formats, including MJPEG, H.264, and H.265. With its high capture rate and global shutter mode, it accurately tracks and records fast-moving forklifts with great detail. In the process, motion blur is eliminated, as well.

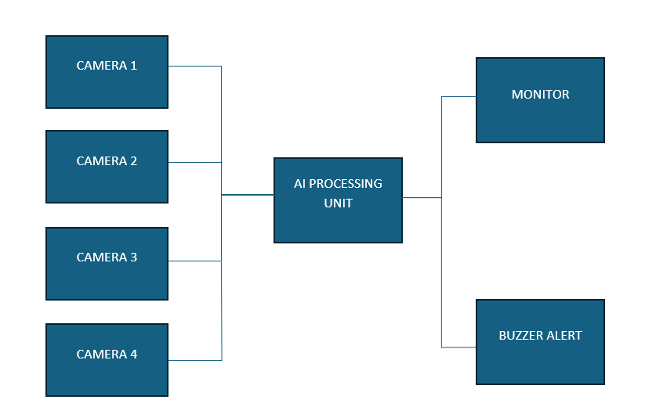

It is important to note that forklift safety solutions can be built using different system architectures. Some leverage external processing units for AI analytics, while others have AI capabilities integrated within the camera itself.

The diagram below shows how a vision-based system uses RouteCAM_CU25.

Key Features of RouteCAM_CU25 That Overcome Forklift Safety Challenges

Enhanced visibility and awareness

One of the primary safety challenges in forklift operations is limited operator visibility. As discussed earlier, blind spots can lead to collisions with pedestrians, other vehicles, and obstacles. RouteCAM_CU25 addresses this issue by providing high-definition video feeds with a global shutter sensor that minimizes motion blur.

The camera’s onboard Image Signal Processor (ISP) adjusts the camera settings to optimize image quality in varying lighting conditions for clear footage. This enhanced visibility reduces the risk of accidents, making forklift operations safer and more efficient.

Multi-camera synchronization

Multiple RouteCAM_CU25 cameras can be synchronized to provide a 360-degree surround-view, enhancing driver awareness and forklift safety. This setup integrates images from various cameras positioned strategically around the forklift, ensuring no blind spots remain uncovered.

For instance, rear-view cameras display the area behind the forklift, assisting in safe reversing. Side-view cameras cover the blind spots on either side, improving safety during turns. Additionally, 360-degree cameras offer an all-encompassing view of the surroundings, ensuring total situational awareness.

With Precision Time Protocol (PTP) synchronization, RouteCAM_CU25 achieves sub-microsecond levels of time synchronization for precision-critical applications and ensures that frames captured by multiple Ethernet cameras are precisely synchronized. It is beneficial in large or complex workspaces like warehouses, where a single camera might not cover all areas.

Rugged and reliable design

RouteCAM_CU25 is housed in an IP67-rated enclosure, making it resistant to dust, dirt, and water ingress. This rugged design ensures reliable operation in harsh outdoor environments, which is crucial for maintaining safety in demanding industrial settings. The camera meets industrial-grade standards such as ISO 16750 and ISO 20653:2013, ensuring it can endure extreme temperatures while guaranteeing durability.

RouteCAM_CU25’s Power-over-Ethernet (PoE) capability simplifies installation and eliminates the need for separate power supplies, making it ideal for use in remote locations or areas with limited power outlets.

Real-time monitoring and alerts

RouteCAM_CU25 camera provides live video with low latency that empowers operators to see what’s happening around the forklift in real time. The camera’s video feeds can detect potential hazards and alert operators immediately. For instance, if a pedestrian enters a defined region of interest (ROI), an automated alert system can notify the operator, allowing for quick action to prevent an accident.

Additionally, the camera’s output pin can be connected to an emergency light or buzzer, providing an immediate visual or auditory alert in hazardous situations.

GigE interface

RouteCAM_CU25 features a Gigabit Ethernet (GigE) interface. It enables the transfer of high-quality video data over long distances (up to 100 meters) without the need for signal boosters or repeaters. It also comes with cable customization options for flexible installation in industrial settings. This is extremely useful in warehouses or manufacturing floors where forklifts operate.

Easy configuration and control

RouteCAM_CU25’s easy integration with e-con Systems’ CloVis Central™ platform allows comprehensive remote management of all on-field device operations, streamlining maintenance processes and reducing downtime. CloVis Central also helps cut down costs associated with camera management by optimizing processes and minimizing resource involvement.

Read more about how RouteCAM_CU25 meets your warehouse safety needs.

e-con Systems Offers Exceptional Camera Solutions for High-Risk Industrial Settings

Since 2003, e-con Systems has been designing, developing, and manufacturing OEM cameras, offering comprehensive solutions for enhancing forklift safety. We have an impressive track record of empowering industrial applications with best-fit camera solutions, even those operating in harsh environments.

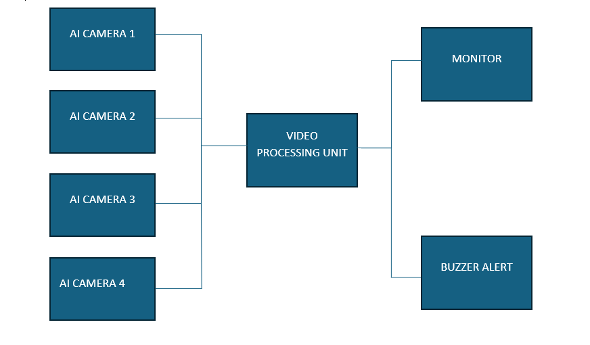

ForkVista, e-con Systems’ upcoming rugged smart camera, will set a new benchmark in forklift safety by combining advanced imaging with real-time AI-based hazard detection and ONVIF support for seamless integration.

Powered by a Full HD Global Shutter sensor and an onboard NPU, ForkVista is built to recognize and alert drivers about potential threats, such as nearby pedestrians. This will help prevent collisions and ensure smoother warehouse operations.

The diagram below shows how an AI-enabled system can use ForkVista.

Visit our Camera Selector Page to explore our full portfolio.

Visit our Camera Selector Page to explore our full portfolio.

For expert assistance in integrating a high-performance camera to boost forklift safety, please contact camerasolutions@e-consystems.com.

Suresh Madhu is the product marketing manager with 16+ years of experience in embedded product design, technical architecture, SOM product design, camera solutions, and product development. He has played an integral part in helping many customers build their products by integrating the right vision technology into them.