The solution lies in polymer-based lens technology. Instead of a motor, this TLens utilizes a special piezoelectric that changes shape when a voltage is applied to it.

The use of Piezoelectric MEMS-based TLens autofocus technology in the camera eliminates the need for moving parts, addressing the core problems of VCM-based technology. The result is a camera that offers faster autofocus, increased durability, and high-quality images.

In this blog, we’ll walk you through

- How TLens technology differs from traditional VCM autofocus

- How TLens combined with e-con Systems’ TintE ISP enhances camera performance

- Key advantages of TLens over mechanical autofocus systems

- Applications of TLens in embedded vision

What is TLens?

TLens® (by poLight ASA (OSE: PLT) ) is a MEMS-based tunable lens that utilizes a PZT (lead-zirconate-titanate) piezoelectric actuator to deform a glass membrane and polymer optic, adjusting focus via voltage rather than moving the entire lens. It supports resolutions from a few megapixels up to very high (30-50 MP) in some designs and is compatible with sensor formats up to 1/1.5-inch.

TLens also has a fast response time (≈approximately 1 ms), low power consumption, and allows focus from infinity down to around 10 cm (or closer, depending on the variant).

The conceptual diagrams are shown below:

Operational Overview of TLens using TintE ISP

Operational Overview of TLens using TintE ISP

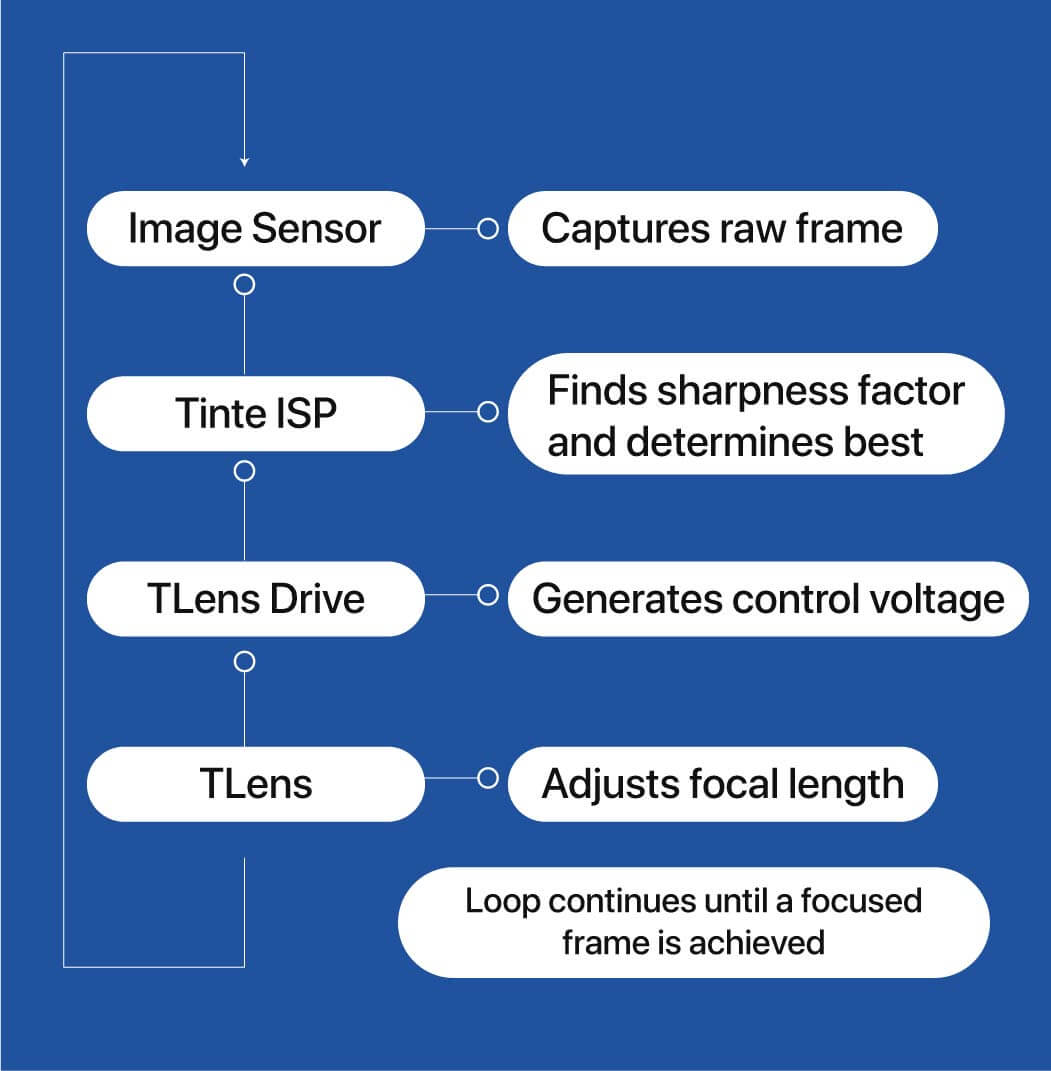

The process begins when the image frame is captured by the image sensor. This data is then sent to an e-con Systems’ Proprietary TintE ISP, an FPGA (Field-Programmable Gate Array) based ISP designed to enhance camera system image quality. The TintE™ provides a comprehensive ISP pipeline, featuring customizable blocks such as debayering, AWB, AE, gamma correction, and more.

The ISP evaluates the captured image frame and then determines the necessary focal adjustment, sending an electrical signal to the TLens, which is mounted on top of a fixed-focus camera module.The flow diagram below helps understand the image processing of the TLens autofocus camera:

The ISP applies a precise voltage to the TLens. This voltage alters the shape of the polymer inside the lens, instantly changing the focal length without any mechanical movement.

The result is a camera that achieves near-instantaneous autofocus, delivering smooth and sharp images while eliminating the mechanical wear and vibration common in VCM-based cameras.

Key Advantages of TLens Autofocus Camera

-

Fast Autofocus for Instant Clarity

With a response time of less than 1 ms, cameras equipped with TLens can lock focus almost instantly. This enables crystal-clear image capture in fast-moving environments such as robotics or autonomous vehicles.

Also Read: How to achieve enhanced autofocus performance with high-quality cameras – e-con Systems

-

Consistent Field of View for Seamless Imaging

Unlike VCM-based autofocus, which can cause shifts in the field of view during focusing, TLens maintains a constant FOV. For the camera, this means smoother video recording and distortion-free imaging—perfect for applications where consistency and reliability are critical.

-

Stable Optical Axis for Superior Image Quality

TLens eliminates mechanical vibrations by using polymer deformation instead of moving parts. Cameras benefit from a rock-solid optical axis, delivering sharp, stable images without the need for complex calibration or correction.

-

Ultra-Low Power Autofocus

Consuming less than 1 mW, TLens ensures the camera operates efficiently without increasing the sensor’s temperature. This improves image quality and extends the camera’s reliability in power-sensitive environments.

-

Compact Size for Multi-Camera Designs

The slim profile of TLens allows cameras to be packed closer together in multi-camera systems. This unlocks new possibilities for advanced vision setups such as stereo imaging, depth sensing, and wide-area surveillance—all without compromising image quality.

-

Wide Aperture for Brighter Images

With an aperture of f/1.55, TLens-equipped cameras can capture more light, delivering brighter and sharper images even in low-light conditions. This is critical for applications like surveillance, automotive, and medical imaging, where detail cannot be compromised.

-

Flexible Focus Range from Infinity to 10 cm

TLens autofocus cameras can seamlessly shift focus from infinity down to just 10 cm. This enables the autofocus camera to handle both close-up inspections and the capture of distant objects.

TLens vs. VCM Technology

| Parameter | TLens | VCM |

| Speed | Near-instant (<1 ms) | Slow |

| Reliability | Very high | Low (wear & tear) |

| Power Consumption | <1 mW | High |

| Constant Field of View | Yes | No |

| Image Stability | Excellent (no vibration) | Low |

| Size (Camera Module) | Ultra-compact | Larger |

| Temperature Stability | High | Low |

| Magnetic Interference | Immune | Affected |

Popular Applications of TLens Cameras in Embedded Vision

Industrial

TLens cameras are exceptionally well-suited for industrial barcode readers due to their incredibly fast autofocus and sub-millisecond response time. This speed is crucial for capturing and processing data from fast-moving objects on production lines, ensuring immediate and accurate reading.

By instantly adjusting their focus, these cameras eliminate the delays associated with traditional mechanical autofocus systems. This makes them a popular choice for enhancing productivity and reliability in industrial handhelds and AI robotic applications.

Biometrics

TLens is specially optimized for the near-infrared (NIR) spectrum, ensuring superior performance in biometric and security applications. This wavelength range is widely used in facial recognition, iris scanning, and vein pattern authentication. Hence, cameras can deliver sharp, reliable autofocus even in low-light or IR-only conditions.

Life Sciences

TLens autofocus cameras offer an ultra-compact design, instant focusing (<1 ms), and low power consumption, making them ideal for integration into endoscopes.

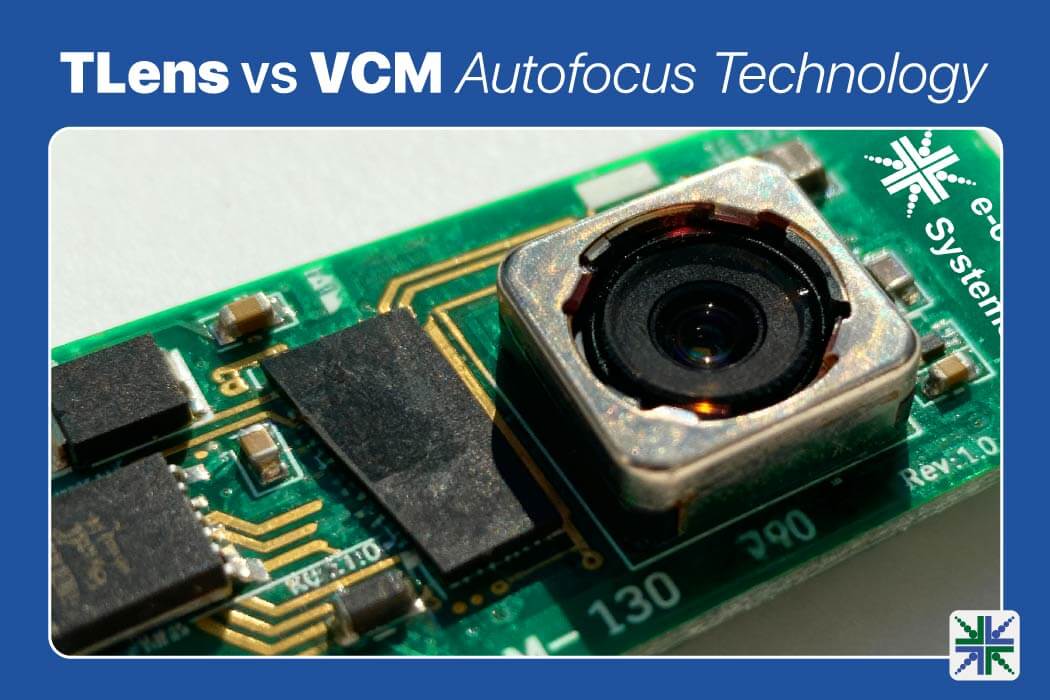

e-con Systems: Spearheading innovative camera solutions

Since 2003, e-con Systems has been at the forefront of designing, developing, and manufacturing OEM camera solutions. Our long-standing expertise ensures that every product we deliver is built for performance, reliability, and seamless integration.

We are actively working on integrating TLens technology into our cameras. By combining cutting-edge TLens technology with our proprietary TintE ISP, our autofocus cameras could achieve <1 ms response time, consume less than 1 mW of power, and come in ultra-compact designs ideal for multi-camera setups.

Contact us at camerasolutions@e-consystems.com to learn how TLens-enabled cameras can accelerate your product development.

Explore our Camera Selector Page to view our full portfolio.

FAQs

- How does TLens improve image stability compared to VCM cameras?

Since TLens eliminates mechanical moving parts, it maintains a stable optical axis during focusing, reducing vibrations and preserving consistent image quality.

- How does the TintE ISP interface with the TLens for real-time autofocus?

The TintE ISP, implemented on an FPGA, captures incoming image frames and performs evaluation based on sharpness to determine the best focus. Based on these metrics, it calculates precise voltage adjustments and drives the TLens membrane. This closed-loop operation achieves sub-millisecond autofocus.

- How does the piezoelectric actuation mechanism in TLens achieve focal length modulation?

The TLens uses a PZT (lead zirconium titanate) MEMS membrane that deforms proportionally to the applied voltage. The deformation alters the curvature of the optical polymer interface, resulting in continuous changes in focal length without axial lens movement.

- Are there limitations to TLens?

- Temperature sensitivity (liquid crystal properties vary with temp).

- Needs a good ISP feedback loop for accurate control

- What is the typical lifetime of a TLens?

Since it has no moving parts, TLens can withstand millions of focus cycles, far exceeding mechanical autofocus lenses in reliability.

Prabu is the Chief Technology Officer and Head of Camera Products at e-con Systems, and comes with a rich experience of more than 15 years in the embedded vision space. He brings to the table a deep knowledge in USB cameras, embedded vision cameras, vision algorithms and FPGAs. He has built 50+ camera solutions spanning various domains such as medical, industrial, agriculture, retail, biometrics, and more. He also comes with expertise in device driver development and BSP development. Currently, Prabu’s focus is to build smart camera solutions that power new age AI based applications.