Key Takeaways

- Occurrence of PPE gaps like lighting shifts, blind corners, fast posture changes, more

- How smart cameras deliver a continuous view of helmets, vests, gloves, and boots

- How features like HDR, global shutter, and others keep visibility stable

- Why vision-led PPE checks are a game-changer for supervisors

Industrial floors constantly undergo several disparities throughout the day. Lighting changes as machinery powers up, shadows form near high racks, and reflective surfaces distort visibility. Crews move fast across aisles, platforms, and loading points, leaving supervisors with only split-second windows to confirm helmets, vests, gloves, and boots.

Even the most disciplined teams struggle during maintenance or dispatch cycles!

Temporary work zones, visiting contractors, and mixed patterns add further unpredictability that can slip past the human eye. For instance, a missing helmet during a quick tool drop or gloves removed during equipment checks.

In this blog, you’ll learn how smart cameras reinforce PPE assurance, reveal visibility gaps that manual checks miss, and give stronger control.

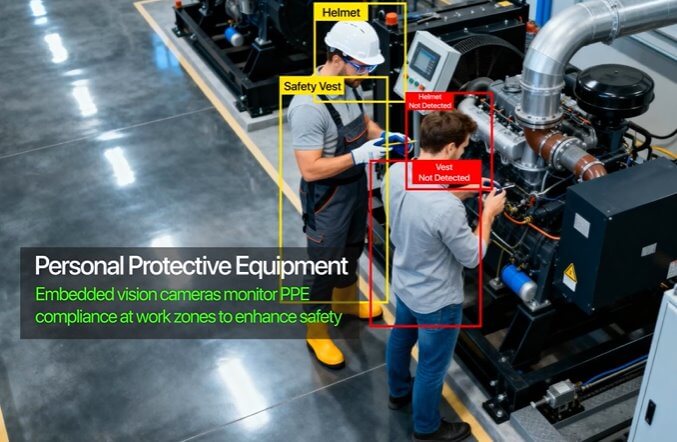

PPE Non-Compliance: What Smart Cameras Actually Spot in Real Time

AI-powered smart cameras study movement, posture, lighting variations, and scene depth in busy floors. They track how crews enter work zones, carry materials, operate machinery, and transition between tasks, all while holding clarity through glare, shadow, vibration, and dust. Gear visibility stays steady even when workers tilt their heads, crouch, or turn away from the lens.

Such a continuous view offers stronger awareness, spanning corridors, platforms, and inspection points where PPE usage can quietly slip.

- Helmet checks – entrances, walkways, and elevated points

- High-visibility vest tracking through long aisles with glare or dust

- Glove verification near stations where hand placement varies

- Boot checks around machinery zones with tight movement paths

- PPE confirmation the moment crews step into regulated areas

What Are the Camera Capabilities That Strengthen PPE Assurance?

Wide FoV for dynamic workflows

Wide FoV smart cameras capture full activity in aisles, platforms, and docking zones without blind corners. They provide broad coverage that retains continuity as scenes change. The reach supports reliable PPE checks across long paths, busy intersections, and overhead positions. It also keeps supervisors informed even when traffic grows dense.

HDR for mixed and harsh illumination

Smart cameras with strong HDR handle sudden brightness spikes from welding arcs, open bays, reflective surfaces, and sunlit loading points. Gear colors stay clear even when shadows stretch across the frame or lights flicker during machine cycles. It helps PPE checks stay consistent and reduces missed cues during fast transitions.

Low-light performance for early and late shift cycles

Many safety gaps emerge during dim hours, inside storage racks, or near enclosed machinery. AI-based smart cameras tuned for low-light keep helmets, vests, gloves, and boots visible without washing out detail. It supports entrances during pre-dawn check-ins and late dispatch runs. It also helps detect PPE gaps inside areas with minimal illumination.

Global shutter for fast-motion scenes

Smart cameras with global shutter capture sharp frames even when workers move quickly between stations, handle power tools, or operate near conveyor edges. Motion blur stays controlled, which keeps PPE outlines clean and dependable. It helps safety teams follow activity during high-speed workflows. It also supports clear tracking of forklifts and autonomous carts.

ONVIF Compliance

AI-enabled cameras built with ONVIF compliance integrate directly into existing Video Management and Network Recording platforms. This allows organizations to centralize real-time monitoring, centralize alerts and video logs, and retain investigative data. ONVIF-compliant systems also scale seamlessly to include additional cameras or devices, making them ideal for large-scale deployments.

High frame consistency for edge inference

AI-powered smart cameras built for steady frame output help edge modules run PPE checks with smooth timing. This matters during crowded intervals when many workers pass through a lane at once. Consistent frames reduce drops in detail as crews change posture or visibility angles. It also supports reliable timestamps for incident review.

Ruggedness for tough industrial conditions

Durable enclosures withstand dust, heat, vibration, and airborne debris in demanding floors. So, with a rugged smart camera, PPE checks continue even during heavy equipment cycles. It also enables placement near machinery where vision hardware usually struggles.

How e-con Systems empowered a top US client with a smart HDR camera for surveillance

Read: 7 Camera Features to Improve Occupational Safety and Health

How e-con Systems’ Smart Cameras Strengthen PPE Compliance

e-con Systems has been designing, developing, and manufacturing OEM cameras since 2003.

We provide AI-led smart cameras that are made for long-duty environments where dust, vibration, glare, and crowded movement cycles are routine. Our cameras ensure clarity despite fast posture changes or busy walkways. Hence, supervisors get a continuous record of helmets, vests, gloves, and boots.

Highlights of what we offer:

- Smart cameras with Sony STARVIS and global shutter sensors maintain clarity despite glare-heavy bays, shaded corners, and dust pockets common in OSH zones.

- GigE, GMSL2, MIPI, and USB options support short-station checks, long cable runs, and multi-camera layouts purpose-built for industrial safety floors.

- Onboard ISP tuning stabilizes exposure and color under welding arcs, reflective surfaces, and sudden brightness dips.

- Rugged IP67 camera builds can withstand conditions like heat, airborne debris, vibration, and outdoor conditions common in OSH corridors, logistics yards, and construction sites.

View all our smart cameras for smart surveillance

Visit our Camera Selector Page to browse e-con Systems’ full portfolio.

If you’re looking for vision experts to help find, customize, and integrate a smart camera into your surveillance system, please write to camerasolutions@e-consystems.com.

FAQs

- How do smart cameras keep PPE cues visible across fast-moving floors?

Smart cameras stabilize exposure, color, and contrast even when workers move quickly or pass through glare-heavy sections. Strong HDR, global shutter capture, and ISP tuning help preserve helmet, vest, glove, and boot outlines during high-speed activity.

- Why do PPE slipups still surface even with training and routine checks?

Lighting changes, dust forms pockets, platforms create blind corners, and crews move across paths with limited supervisor visibility. Smart cameras fill these gaps by studying movement and gear cues.

- Which work zones benefit most from smart camera coverage?

Busy segments such as forklift aisles, welding bays, scaffolding routes, elevated walkways, and conveyor paths gain steady visibility. These zones carry frequent posture variations and fast motion, making PPE checks harder to sustain through manual oversight.

- How do smart cameras support OSH during low-light or mixed-light cycles?

Low-light performance and wide dynamic range help cameras retain clarity during pre-dawn check-ins, late dispatch cycles, or sections where natural and artificial light blend. Gear colors and outlines stay readable even when illumination can vary sharply.

- What makes e-con Systems a strong vision partner for PPE compliance projects?

e-con Systems provides smart cameras designed for dust, vibration, heat, and heavy movement in industrial corridors. They came with imaging features like powerful Sony STARVIS sensors, global shutter mode, rugged IP67 enclosures, and multiple interface choices that support long-duty OSH deployments.

Ram Prasad is a Camera Solution Architect with over 12 years of experience in embedded product development, technical architecture, and delivering vision-based solution. He has been instrumental in enabling 100+ customers across diverse industries to integrate the right imaging technologies into their products. His expertise spans a wide range of applications, including smart surveillance, precision agriculture, industrial automation, and mobility solutions. Ram’s deep understanding of embedded vision systems has helped companies accelerate innovation and build reliable, future-ready products.